Project Name: Salt Lake International Airport Cargo Apron Project – Salt Lake City, Utah

Owner: Salt Lake International Airport

Contractor: Ames Construction

Engineering Firm: JViation

Date: September 2021 – Present

Manufacturer: Oldcastle Infrastructure

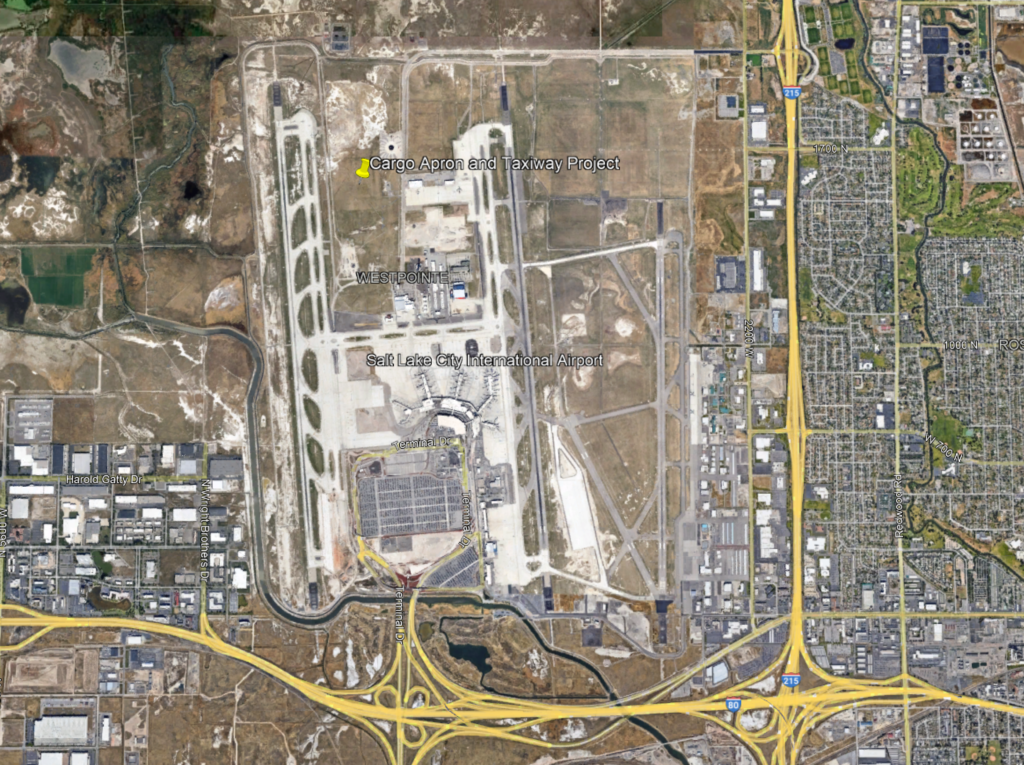

Location: North end of Salt Lake International Airport

Product Specifications: (size, material, etc.): 2,952 feet of 54-inch Class V RCP, 1,232 feet of 36-inch Class V RCP, 288 feet of 30-inch Class V RCP, 576 feet of 24-inch Class V RCP, 1,368 feet of 18-inch Class V RCP, two 7′ x 9′ precast concrete meter vaults (5 feet tall with 14-inch thick walls, 30-inch footing all the way around to prevent flotation, with a weight of 73,000 pounds), and one oil/water separator in an 8′ x 16′ precast concrete vault.

Overview:

The Salt Lake International Airport is installing a new cargo apron and taxiway on the north west side of the airport. In order to handle all of the drainage and runoff from the impervious area, and meet the load requirements, the contractor is installing Class V RCP and an oil/water separator.

Photo courtesy of Google Earth

Narrative:

Construction on the new Salt Lake International Airport began in the summer of 2016. To date, over 40,000 feet of Class V reinforced concrete pipe has been installed on the project. There are a lot of unique design considerations at the airport which make RCP a great choice for drainage pipes. First, there is an abundance of impervious area, which results in a large amount of runoff. Second, FAA design loading is high, which means you need a strong, resilient pipe product to handle the loads. Third, there is a high probability of fires on an airport, so flammable products like thermoplastic pipes provide additional risks. Fourth, groundwater is high near the airport, so you need a heavy product, like concrete, to reduce the risk of flotation. Lastly, the design specifications required mandrel tests for flexible pipe.

Based on all the factors discussed above, RCP was the preferred choice of pipe on the airport project. Based on the strict mandrel requirements and the potential for burning of the leach ponds, approximately 8,000 feet of plastic pipe was swapped out for reinforced concrete pipe.

On the north end of the airport, just north and west of the air traffic control tower, the FAA is installing a new cargo apron and taxiway. This project also ties in to an existing 60-inch concrete drainage pipe. Because of the large impervious area of aprons and taxiways, projects like this require significant BMPs (Best Management Practices) for storm water quality. For this project, a large 8′ x 16′ precast vault with an oil/water separator, was installed to treat runoff prior to entering the storm drain system.

The Salt Lake International Airport is plagued with high ground water, which causes significant potential for flotation of underground utilities. Because of the weight of reinforced concrete pipe, it is less likely to float and does not require additional bracing or anchors. However, utility vaults and catch basins with large, flat bases increase the possibility of flotation in high ground water situations, like at the airport. As such, one possible solution is to manufacture the base with a wider footing. The weight of the fill material on top of the footing helps offset the upward buoyancy forces. For this project, the utility vaults had 30-inch footings all the way around the base, and to meet the FAA design loading requirements, the lids of the vaults were 15 inches thick.

For the cargo apron project, the following precast concrete products were used: 2,952 feet of 54-inch Class V RCP, 1,232 feet of 36-inch Class V RCP, 288 feet of 30-inch Class V RCP, 576 feet of 24-inch Class V RCP, 1,368 feet of 18-inch Class V RCP, two 7′ x 9′ precast concrete meter vaults (5 feet tall with 14-inch thick walls, 30-inch footing all the way around to prevent flotation, with a weight of 73,000 pounds), and one oil/water separator in an 8′ x 16′ precast concrete vault..