Project Name: Park Valley Commercial – South Jordan, Utah

Owner: Peterson Development

Contractor: Salt Lake Excavating

Engineering Firm: Anderson Wahlen and Associates

Date: February 2021

Manufacturer: Oldcastle Infrastructure

Product Specifications: (size, material, etc.): 1,400 linear feet of 60-inch Class III RCP

Photo courtesy of Oldcastle Infrastructure

Overview:

This project included the installation of over 1,400 linear feet of reinforced concrete pipe. In order to handle the runoff from the development, the design called for 60-inch, Class III pipe.

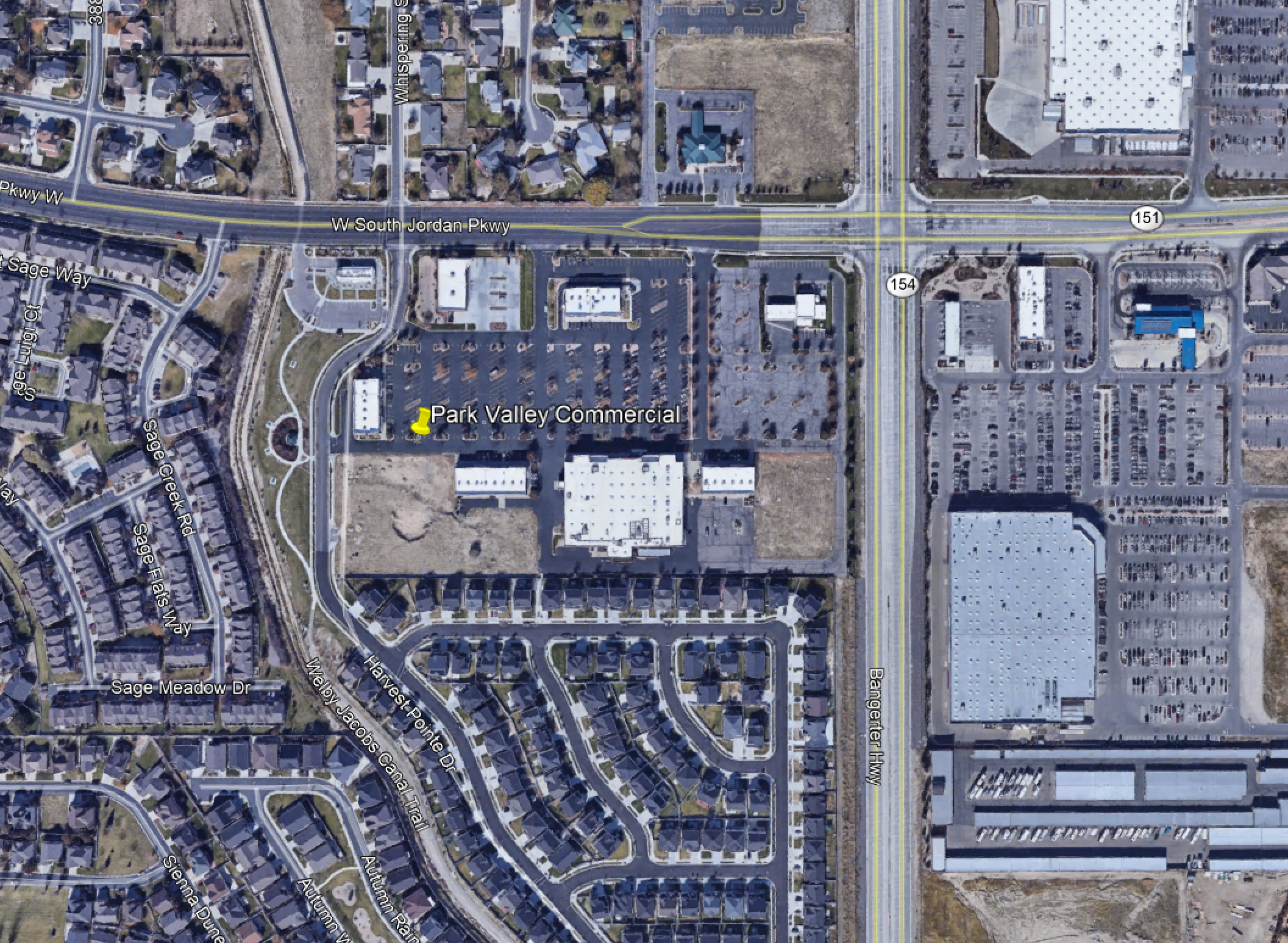

Photo courtesy of Google Earth

Narrative:

This project is part of a larger Commercial Community Planned Development project by Peterson Development. This commercial portion of the project is located at approximately 3775 West South Jordan Parkway.

Photo courtesy of Oldcastle Infrastructure

Because of the large flows and the low cover depth, the project engineer chose to use reinforced concrete pipe. These particular 60-inch sections of pipe were 12 feet long, instead of the typical 8-foot sections that are common in smaller diameter pipes. RCP requires less lifts during construction than flexible pipe, so it installs quickly once it is in the trench.

Photo courtesy of Oldcastle Infrastructure

Reinforced concrete pipe can handle heavy loads compared to other flexible pipe options. Approximately 90% of the structural load is carried by the pipe itself, with the remaining 10% borne by the bedding and backfill material. Conversely, flexible pipe typically only carries 10% of the load, while the bedding and backfill provide the vast majority of the structural support. This makes RCP a great option for situations with low cover both during construction and in the final condition.

Photo courtesy of Oldcastle Infrastructure

Typically, a section of pipe will need to be sawcut to the correct length based on the engineering plans. While this is a relatively simple task on small diameter pipes, it requires a little more foresight on larger diameter pipes. Both ends of the pipe must be stabilized and secured to ensure that there is no movement before, during and after the sawcutting process. Once the end section is removed, the pipe is ready to place in the trench.

Photo courtesy of Oldcastle Infrastructure