Project Name: Little Bear River Bridge – Wellsville, Utah

Owner: Wellsville City

Contractor: Legrande Johnson

Engineering Firm: Jones and Associates (Wellsville City Engineers)

Date: July-August 2021

Manufacturer: Oldcastle Infrastructure

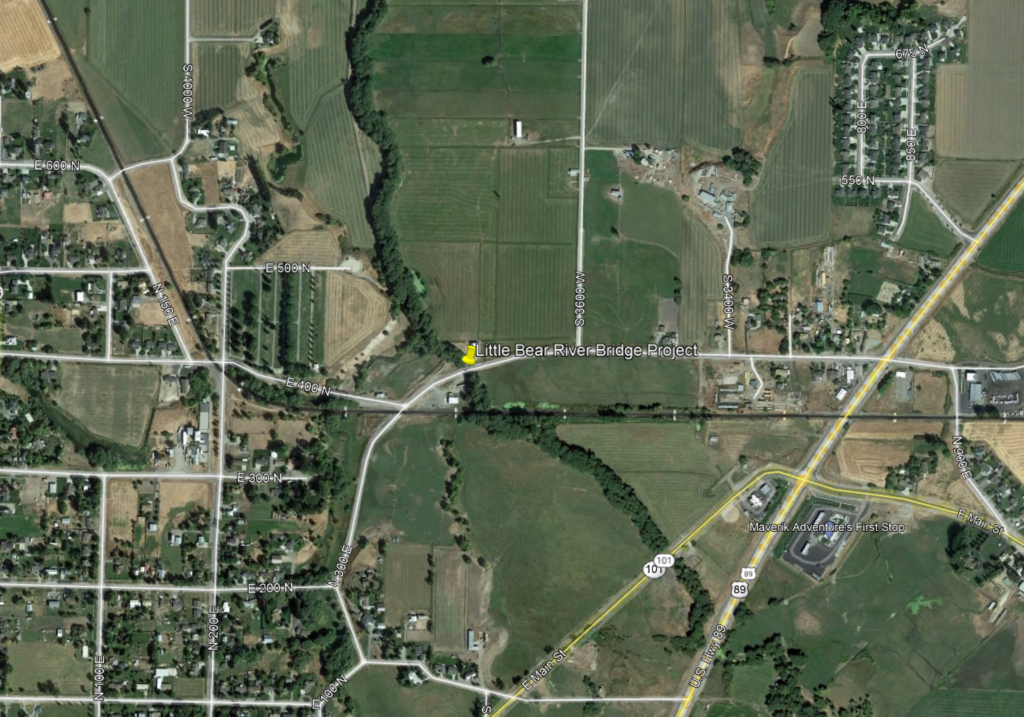

Location: approximately 400 North and 4700 West, Wellsville, UT

Product Specifications: (size, material, etc.): 7 sections of 29-feet wide x 15-feet tall, three-sided precast concrete box culvert, and precast concrete footings; weight of each culvert section is approximately 38 tons

Photo courtesy of Oldcastle Infrastructure

Overview:

Wellsville City decided to replace a narrow, 100-year old concrete bridge and corrugated metal culvert with with a large, 29′ x 15′ three-sided precast concrete box culvert over the Little Bear River less than a mile west of US-89.

Photo courtesy of Google Earth

Narrative:

For years, motorists travelling west on 4700 West off of US-89 in Wellsville, Utah, would come across a narrow, one-lane bridge over the Little Bear River. The actual age of this concrete bridge structure is unknown, but it is estimated to be over 100 years old. Having served its reasonable life span, the City of Wellsville chose to widen the bridge and replace an aging corrugated metal culvert adjacent to the old bridge.

Photo courtesy of Oldcastle Infrastructure

In order to replace the bridge as quickly as possible, and to expand the bridge section to accommodate two lanes of traffic, the City chose to use a three-sided precast box culvert. Based on the flow requirements of the Little Bear River, the City Engineers designed the box culvert to be 29 feet wide (near the maximum width that the precast manufacturer could provide) and 15 feet tall. Additionally, the engineer chose to use precast concrete footings to further accelerate construction.

Because the Little Bear River flows year round, the box culvert had to be installed while the river was flowing. This is the main reason that the engineer chose to use a three-sided box culvert. The area around the existing corrugated metal culvert was excavated and the precast concrete footings were installed. The corrugated metal culvert was left in place while the seven sections of 3-sided box culvert were installed over the top of the CMP. Once the box sections were in place, the contractor then backfilled around the box, restored the creek bed inside the box, and removed the corrugated metal culvert.

Photo courtesy of Oldcastle Infrastructure

The contractor installed the box culvert sections at two different times due to conflicts with overhead power lines. The crane set five sections on the footings to the north, and then moved them into place to the south after the power company came and gave them clearance to work under the power lines. According to the City Engineer and the contractor, the installation went well and aside from the overhead power conflicts, there were no major issues or setbacks.

Photo courtesy of Oldcastle Infrastructure

Installation Video:

The following video shows the installation of one of the pieces of the 29′ x 15′ three-sided, precast concrete box culvert.